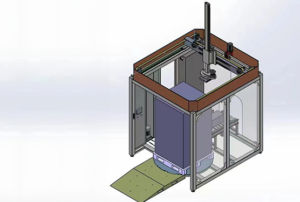

Vertical Form Fill and Seal Packaging Machine

High performance and reliable with intermittent or reciprocating continuously motion Vertical Form Fill And Seal (VFFS) Machine

Designed for forming bag from film, Filling it by synchronized dosing system, sealing it and outputting.

VFJ series is able to make pillow bag, flat-bottom bag, quad seal bag, vacuum bag, vent valve bag and M shape guesset bag.

Technical Features:

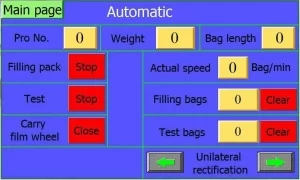

- Famous Brand PLC

Double servo motors for pull-ing film down system - Automatically film rectifying function

- Many kinds of languages can be chosen

- Adopt clip or supporting without broken bags; reduce

waste

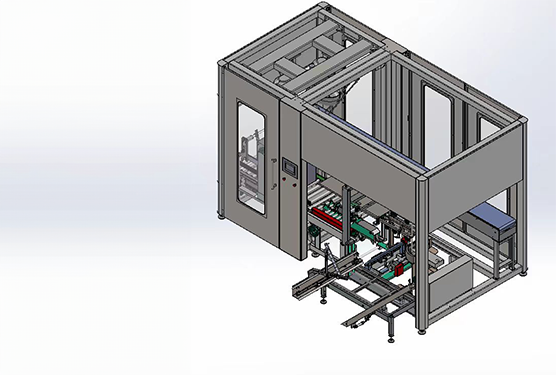

VFFS Packaging Solutions

Customer Success Project, Customized Packing Solutions

Hot Sale VFJ Series Pillow Packaging Machine

High-Speed Automation for Optimal Results: Unleash the Potential of the VFFS Pillow Packaging Machine

-

Vertical Form Fill and Seal Packaging Machine

Multilane Sachet Packaging Machine VFM

Rated 0 out of 5 -

Vertical Form Fill and Seal Packaging Machine

Vertical Form Fill And Seal Machine VFJ-720

Rated 0 out of 5 -

Vertical Form Fill and Seal Packaging Machine

Continuous Motion packing Machine VFJ-520V

Rated 0 out of 5 -

Vertical Form Fill and Seal Packaging Machine

Intermittent VFFS Vertical Form Fill And Seal Machine VFJ-420

Rated 0 out of 5

| MODEL | VFJ-420 | VFJ-520 | VFJ-720 | VFJ-920 | VFJ-1200 | VFJ-520V |

|---|---|---|---|---|---|---|

| Baglength | 50-310mm(L) | 80-360mm(L) | 80-410mm(L) | 100-570mm(L) | 100-720mm(L) | 50-400mm(L) |

| Bag width | 50-200mm(W) | 80-250mm(W) | 100-350mm(W) | 180-450mm(W) | 200-580mm(W) | 100-250mm(W) |

| Max roll fifilm width | 420mm | 520mm | 720mm | 920mm | 1200mm | 520mm |

| Packing speed | 10-70bag/min | 5-60 bag/min | 5-60 bag/min | 5-40 bag/min | 5-30 bag/min | Max. 180 bags / min |

| Air consumption | 0.3m³/min | 0.4m³/min 1.0Mpa | 0.4m³/min 1.0Mpa | 0.5m³/min 1.0Mpa | 0.5m³/min 1.0Mpa | 0.4m³/min 0.7Mpa |

| Power voltage | 220VAC/50/60Hz | 2.7kW 220V 50/60HZ | 3kW 220V 50/60HZ | 6KW 220V 50/60HZ | 6KW 220V 50/60HZ | 5KW 220V 50/60HZ |

| Dimension(L)x(W)x(H) | 1080x1300x1400 | 1175x1530x1670 | 1700x1270x1900 | 1750x1510x2100 | 2400x1800x2750 | 1600x1170x1610 |

| Machine weight | 480Kg | 550KG | 700KG | 1000KG | 1200KG | 950KG |

VFFS Packaging Dosing Systems

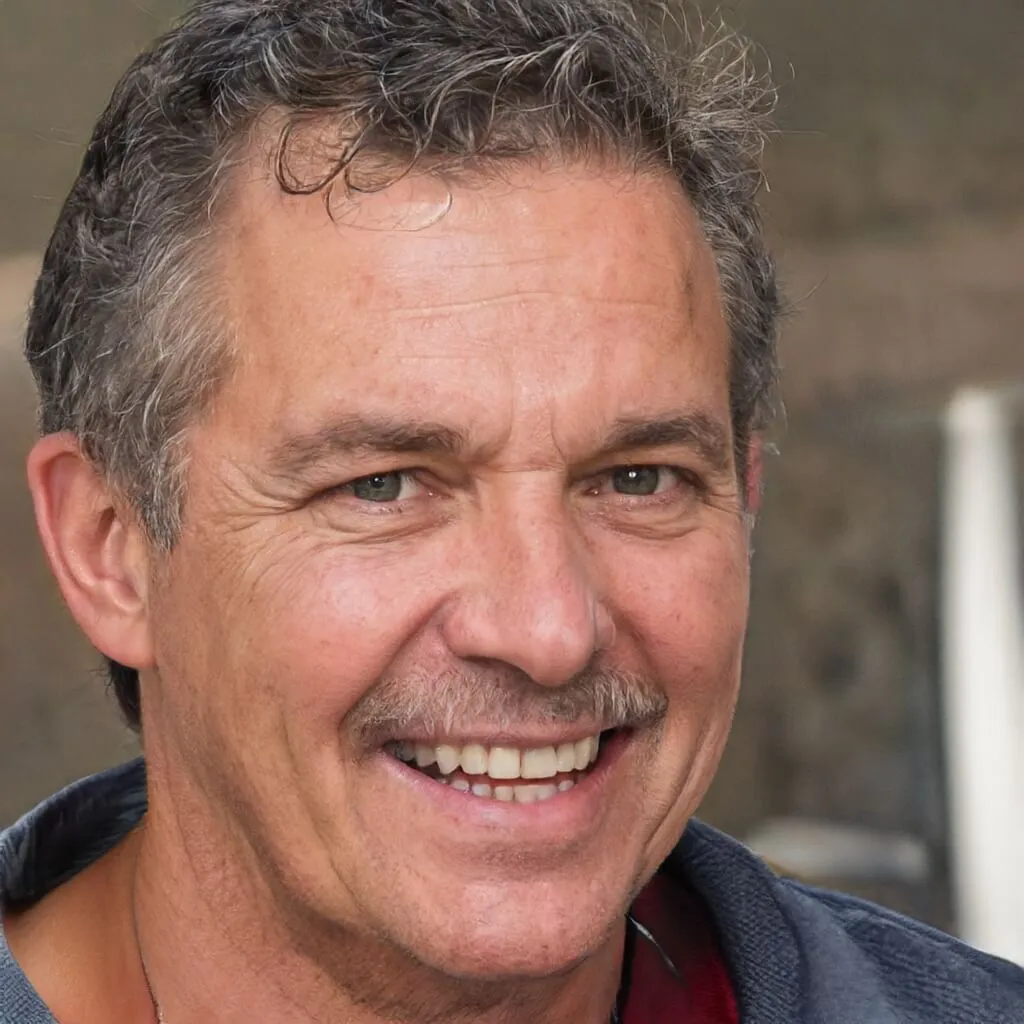

Hey there, l just wanted to share my experience with HonorPack. As a purchasing manager for a snack food production factory, l've been workingwith them for over 5 years now, and l have to say that their bag packaging machinery is top-notch. Their solutions are tailored to our specificneeds, and the machinery is not only durable but also easy to use. Plus, their customer service is outstanding.

I've been in the snack food production industry for over 20 years now, and 've worked with many diferent packaging suppliers. But none of themcompare to HonorPack. Their machinery is not only reliable but also easy to use, and their customer service is outstanding. l would highlyrecommend them to any business looking for a trusted partner in the industry.

All You Need To Know About Vertical Form Fill Seal (VFFS) Machines

Vertical Form Fill Seal (VFFS) machines are an integral part of numerous industries, with applications in food processing, pharmaceuticals, and other sectors requiring efficient, high-speed packaging solutions. Here is an overview of everything you need to know about these machines.

What is a Vertical Form Fill Seal (VFFS) machine?

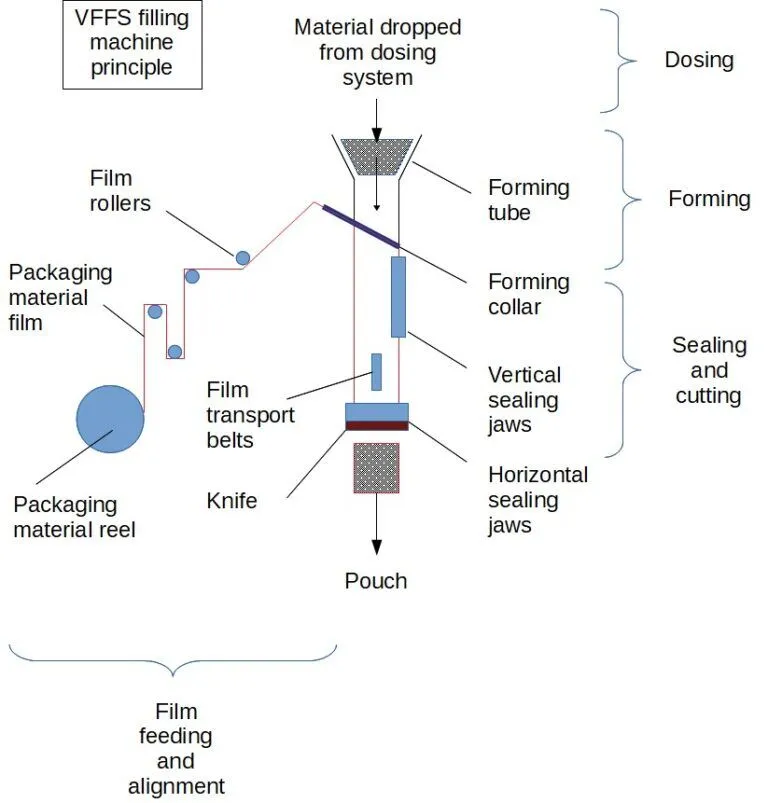

The very essence of a VFFS machine lies in its name: it forms, fills, and seals packages vertically. The automated packaging process starts by feeding a continuous flat roll of plastic film through the machine. The film is formed into a bag shape with the help of a forming collar, following which the product is filled and the bag is sealed. This three-step process—form, fill, and seal—occurs in a vertical manner, hence the name.

Components of a VFFS machine

A typical VFFS machine is made up of several core components, each having a specific function in the packaging process.

Film Roll: The film roll forms the basis of the package. The choice of film material largely depends on the product to be packaged, shelf life requirements, and cost considerations. Plastic films like polyethylene, polypropylene, and various laminates are commonly used.

Forming Collar: The forming collar, or forming tube, takes the flat film and transforms it into a cylindrical shape, effectively creating the “bag” in which the product is filled.

Vertical Seal Bar: Once the film is shaped, the vertical seal bar creates the longitudinal “back” seal of the bag, securing the sides of the bag together.

Filling System: The filling system is a critical part of the VFFS machine. Depending on the product to be packaged, the filling system could be volumetric (for solid products), gravimetric (for products that need to be weighed), or liquid/paste fillers.

Horizontal Seal Bars: The final step in the process involves the horizontal seal bars, which seal the “top” of the bag (which becomes the bottom of the next bag).

All You Need To Know About Premade Pouch Packaging Machines

As the owner of HonorPack, a company specializing in bag packaging machinery, I know firsthand how essential it is to stay up-to-date on the latest developments in the packaging industry. The premade pouch packaging machine has become increasingly popular, and for good reason. It offers an efficient and cost-effective solution for businesses looking to streamline their packaging processes. In this blog post, I’ll guide you through everything you need to know about these machines, including their types, components, and applications.

Premade Pouch Packaging Machines VS VFFS Packaging Machines

Pre-made bag packing machine is a kind of packing machine to fill products into pre-made bags and then seal them. Compared to the VFFS (Vertical Form Fill and Seal Packing Machine, which uses roll film to make bags), it can be used to pack many types and sizes of pre-made bags, and doesn’t have to change machine parts. By packing more attractive packages, this machine will help you win the market. When changing your packing style or packing specifications, also you will save the cost of changing the machine parts or machine models. (Usually VFFS machine can only pack one width type bags, if you change the bag size, you will need change the film size and bag formers.) However the premade bag price will be higher than roll film Bags.

| Pros & Cons | Premade Pouch Packaging Machines | VFFS Packaging Machines |

|---|---|---|

| Flexibility | Can handle various pouch styles (stand-up, flat, zippered, and spouted). | Limited to specific bag styles. Roll film Bags |

| Efficiency | Can handle multiple pouch sizes without changing parts or adjusting the machine. | Continuous operation allows for high speed. Changing the film size and bag formers |

| Quality | Better aesthetics and consistency due to precise manufacturing process and pre-made bag packaging. | Quality may vary due to potential alignment and sealing issues during high-speed operation. |

| Speed | Slower due to the need to open, fill, and seal premade bags. | Typically faster because of the single, continuous operation. |

| Cost | Higher initial investment due to the cost of premade pouches. | Lower material costs as bags are formed from a single roll of film. |

Packaging Process of VFFS Machine

Understanding the packaging process in more detail can help to appreciate the efficiency and versatility of VFFS machines.

- Film Feeding: The process begins with loading the film roll onto the machine. The film is typically guided through a series of rollers to ensure smooth and constant feeding into the forming collar.

- Bag Forming: As the film reaches the forming collar, it is folded into a cylindrical shape. The vertical sealing bar then applies heat and pressure to seal the overlapping edges of the film, forming a continuous tube.

- Filling: While the tube is being formed, the product is simultaneously dropped down the center of the tube. The timing and speed of this process are crucial to ensure the right amount of product is dispensed into each bag.

- Sealing and Cutting: After the product is dispensed, the horizontal sealing bars move in to create the ‘top’ seal of the current bag and the ‘bottom’ seal of the next bag. A cutting mechanism then cuts the filled bag free from the continuous film tube.

VFFS Machine Bag types

One of the biggest advantages of VFFS machines is the variety of bag types they can produce. Depending on the product and specific packaging needs, you can choose from several styles:

Pillow Bags: The simplest and most common bag style, ideal for a wide range of products.

Gusseted Bags: These bags have added volume and stability, making them perfect for bulkier items.

Block Bottom Bags: These bags stand upright on shelves, making them great for retail display.

4-Side Seal Bags: Ideal for flat, non-bulky items. All four sides of the bag are sealed for a uniform appearance, often used for products like coffee, tea, or powdered mixes.

Stick Packs and Sachets: Small, slim bags used for single-serve portions, popular for products like sugar, condiments, or pharmaceutical powders.

Sales always will ask you for the bag type and bag size, also the product type/size and packing weight range.

Here are the table show you the bag type that different machine can pack.

Industry Applications: The Versatility of VFFS Machines

The applications of VFFS machines span across various industries, each leveraging the speed, efficiency, and versatility these machines offer.

Food Industry: VFFS machines are prevalent in the food industry, packaging products like cereals, coffee, spices, snacks, grated cheese, and even fresh produce. The machines are adaptable to handle varying product characteristics – from dry to moist, and from granular to whole pieces.

Pharmaceuticals: These machines provide the precision required in the pharmaceutical industry, often packaging pills, capsules, and powders. Some machines can even package multiple items into a single bag, such as a pill bottle along with an informational leaflet.

Chemicals and Agriculture: VFFS machines are also used to package chemicals and agricultural products like seeds, fertilizers, detergents, and cleaning supplies. These often require specialty films that are resistant to the specific chemical being packaged.

Personal Care: The personal care industry uses these machines for packaging a wide array of products including shampoo, lotions, creams, and even individual wipes. The diversity of bag styles and sizes offered by VFFS machines meet the varied demands of this industry.

Benefits of VFFS machines

The growing popularity of VFFS machines can be attributed to the multitude of benefits they offer:

- Speed: The automation and continuous operation of VFFS machines enable a high production output, making them ideal for industries with high volume requirements.

- Versatility: VFFS machines can handle a wide range of products, from free-flowing solids like cereal, to liquids like juice, and even powders or granules like coffee or detergent.

- Customizability: With adjustable forming collars and multiple sealing options, VFFS machines offer high flexibility in terms of package sizes, shapes, and types.

- Efficiency: By integrating the forming, filling, and sealing processes, VFFS machines streamline the packaging operation, resulting in significant cost and time savings.

-

Vertical Form Fill and Seal Packaging Machine

Vertical Form Fill And Seal Machine VFJ-520

Rated 0 out of 5 -

Vertical Form Fill and Seal Packaging Machine

Continuous Motion packing Machine VFJ-520V

Rated 0 out of 5

Continuous Motion VFFS Machines:

In a continuous motion VFFS machine, the film is always moving. The machine continuously forms, fills, and seals the bags without stopping. This process is achieved through the following steps:

- The film is continuously fed into the machine.

- As the film moves, the longitudinal seal is formed to create a tube.

- The tube is then filled with the product in a continuous motion.

- Horizontal sealing jaws create the top seal of one bag and the bottom seal of the next simultaneously.

- The filled bag is cut off while the film continues to advance.

Continuous motion VFFS machines offer higher packaging speeds, making them ideal for high-volume applications. However, they can be more complex and may require more precise control over the product feed, as the product must be dropped into the moving film tube.

| MODEL | VFJ-520 Intermittent | VFJ-520V Continuous |

|---|---|---|

| Baglength | 80-360mm(L) | 50-400mm(L) |

| Bag width | 80-250mm(W) | 100-250mm(W) |

| Max roll fifilm width | 520mm | 520mm |

| Packing speed | 5-60 bag/min | Max. 180 bags / min |

| Air consumption | 0.4m³/min 1.0Mpa | 0.4m³/min 0.7Mpa |

| Power voltage | 2.7kW 220V 50/60HZ | 5KW 220V 50/60HZ |

| Dimension(L)x(W)x(H) | 1175x1530x1670 | 1600x1170x1610 |

| Machine weight | 550KG | 950KG |

Making the Right Choice:

When deciding between an intermittent and continuous VFFS machine, several factors should be considered:

- Product Characteristics: Certain products may be better suited to one type of machine over the other. For instance, products that are difficult to control during the filling process might be better suited for an intermittent motion machine.

- Production Speed: If high-speed operation is a priority, a continuous motion machine may be the better choice. However, for lower volume or more specialized applications, an intermittent motion machine could be sufficient.

- Budget: Continuous motion machines can be more expensive due to their complexity and higher speeds. If budget is a concern, an intermittent motion machine may be more cost-effective.

Quality Control in VFFS Machines

Quality control is a crucial aspect of the packaging process, ensuring the consistency and integrity of each package.

Weighing Systems: Many VFFS machines incorporate precise weighing systems to ensure each package contains the correct amount of product.

Seal Integrity: Advanced sensing and control systems monitor the heat sealing process to ensure each bag is sealed properly.

Metal Detection: Some VFFS machines include built-in metal detectors to ensure product safety.

Vision Systems: These are used for real-time inspection of the packages for defects or inconsistencies.

VFFS Machines Customization Options

Name | Function |

14 heads combine weigher | Matching with packing machine to reach high speed and accuracy |

10 heads combine weigher | Matching with packing machine to reach high accuracy |

Vibrating hopper | Vibrate feeding |

Z shape elevator | Automatic feeding to the weigher |

Single hopper elevator | Automatic feeding to the volumatic cup device |

Bucket feeder | Manual droping block or fragil product to hopper to reach one dump one pack |

Finished product elevator | Finished product carry away machine |

Round rotating table | Round rotating table for easy picking. |

Auger elevator | Matching with auger filler to elevate powder and flour product |

Vacuum elevator | Elevating material in a good environment. |

Auger filler | Measuring powder and flour product |

Big four head weigher | Suitable for big bulk prodcut measuring and filling |

Weight detecting machine | Selecting finished product which can not reach the target weight |

Factors to Consider When Choosing VFFS Machine

Choosing the right VFFS machine involves several considerations. Understanding the specific needs of your product and operation is crucial in making the right decision. Here are a few factors to consider:

Product Characteristics: The type, size, and consistency of the product will influence the choice of the filling system, the film material, and the bag type.

Production Volume: The required production speed will determine the size and complexity of the machine. High-volume operations may need machines with multiple filling and sealing stations.

Budget: The price of VFFS machines can vary greatly, from simple, single-station machines to complex, multi-station systems. The budget should reflect the requirements of your operation.

Maintenance and Support: Consider the availability of spare parts, technical support, and maintenance services when choosing a VFFS machine.

- Cost:Cost is always a major factor when purchasing new equipment. However, rather than focusing solely on the initial cost, consider the total cost of ownership over the life of the machine, which includes maintenance, energy use, and consumables.

In order to provide you the correct packing equipment for your business. We hope we can get more information from your side. The under questions list will help us reduce the checking time and save time for you. You can download the Excel table at the end of this part.

download the Excel table at the end of this part.

Question List | Your Answer | Note |

01 What kind of product you are going to pack? If we can get some samples/photos to assess? |

|

|

02 Could you tell us the packing weight range? |

|

|

03 Do you have the sample bags and bag size? |

|

|

04 If you can send us your bag photos or design? If you can send us your bags to our factory address to test? |

| If send sample bags need around 100-200 bags. |

05 Could you let us know your plant size or layout? Is there any celling height limit? |

|

|

06 What’s your factory power supply voltage type? |

|

|

07 When you are going to apply this set of machines? |

|

|

08 For self-use or resale to others? Which Country? |

|

|

09 The packing speed requirements. |

|

|

10 Other requirements for the packing process. |

|

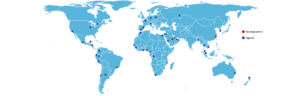

How to Choosing VFFS Machine Manufacturer

When you’re in the market for a Vertical Form Fill Seal (VFFS) packaging machine, the choice of the manufacturer is as important as the machine itself. Here are some factors to consider when choosing a VFFS machine and its manufacturer:

Manufacturer Reputation and Expertise: First and foremost, the reputation and expertise of the manufacturer should be taken into consideration. Research on their experience in the industry, the quality of their machines, and their track record in terms of customer satisfaction.

Machine Features and Capabilities:It’s important to fully understand the capabilities of the VFFS machine you’re considering. Key factors to assess include the types of bags it can produce, its speed, its compatibility with different packaging materials, and its ability to accommodate the specific product you intend to package.

Integration with Your Current Setup: Consider how well the new machine will integrate with your existing production line. Check whether it can seamlessly fit into your current processes or if modifications will be necessary.

Training and Support: A good manufacturer will offer comprehensive training to your staff on the operation and maintenance of the machine. They should also provide a solid after-sales service, including quick response times for technical support and readily available spare parts.

Cost is always a major factor when purchasing new equipment. However, rather than focusing solely on the initial cost, consider the total cost of ownership over the life of the machine, which includes maintenance, energy use, and consumables.

Technology and Innovation:Lastly, consider how forward-thinking the manufacturer is. Do they stay up-to-date with the latest trends and technological advancements in the packaging industry? Are their machines adaptable and upgradeable to accommodate future needs?

Maintaining Your VFFS Machine

Proper maintenance of a VFFS machine is essential for ensuring a long and productive life. Here are some best practices:

Wearing part replacement:

- If the carry film belt wear out, pls loose M6 bolt on the top, replace the belt and

tight the bolt again. - Replace the cutter, loose two M5 bolt and take out the cutter in the cutter groove

(mind the heat if the jaw was heating), replace it and tight the bolt. Also install the

cutter according to the division. - When run out of ribbon, take out the rest of the wheel from the wheel groove

and replace with new ribbon. (pls review the code printer install and using instruction)

VFFS Machine Maintaining:

- On the first running, pls make sure all the bolts are tight, and check form time to

time. If there is any abnormal noise, pls stop the machine immediately. Pls keep the

machine running for 2-3 min after installation or before working. - Check the FRL oil tank, and keep the oil more than 1/3. If oil needed to be

added, pls use 20# pure engine oil - Keep the eyemark sensor clean and keep the electric part from moisture.

- Tighten the bolt of the sealing (if there is any bolt is loose) after stop using the

machine. - Before running the machine, pls add the oil cup full with 20# engine oil.

- Take out the roll film to prevent it bend the roller.

- When running, if broke bag situation happen, pls use emergency stop, and use

cooper brush to clean the sealing jaw. - First change of engine oil of the gear box is 40 hours using. Thereafter, per 1000

hour using should change once. - If the machine haven’t been used for a long time, pls keep the machine running

testing mode for 0.5-1 hour, every 5-6 day once.

Conclusion

In conclusion, investing in a VFFS machine is not just an investment in a piece of equipment; it’s an investment in efficiency, versatility, and the future of packaging. With a keen understanding of the capabilities and advantages of VFFS machines, businesses can leverage these powerful tools to drive their success and growth in the competitive global market.