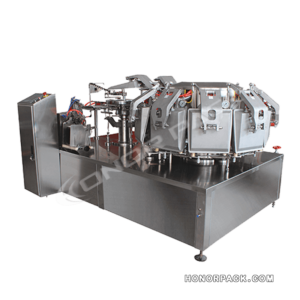

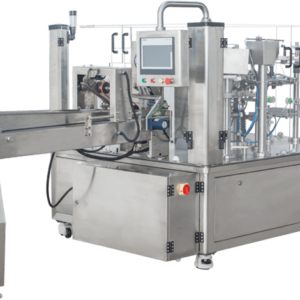

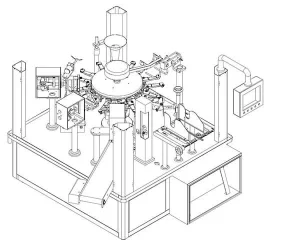

Premade Pouch Rotary Fill & Seal Packing Machine

Premade Pouch Rotary Packing Machine is an automatic packing machine which automatic feeding & pick up pouches, coding, open the pouches, filling products into the pouches, then sealing & output.

- Korea Design & Market Proved

- 10” Touch Screen / Graphic Interface

- Heavy Loading Gripper

- Ready For DoyPack, Zip Pouch

- Change Width In Minutes

- Easy Washing & Cleaning

- Synchronize With Most Of Filler

Hot Sale JR Series Premade Pouch Packaing Machine

The JR Series combining top-quality Korean manufacturing with affordable pricing to deliver customized packaging solutions.

| MODEL | JR-824 | JR-1023 | JR-830 | JR-735 |

|---|---|---|---|---|

| WORK POSITION | 8 | 10 | 8 | 7 |

| WIDTH(MM) | 80-240 | 80-230 | 100-300 | 150-350 |

| LENGTH(MM) | 100-400 | 100-400 | 100-450 | 100-500 |

| DOSING SYSTEM | MULTI-HEAD SCALE,AUGER FILLER,PISTON FILLER,VOLUMETRIC CUP,LINER SCALE | |||

| VOLTAGE | AC380V 50/60HZ3 PHASE,AC110V 60HZ MONO PHASE OR PER REQUEST | |||

| POWER | MAX 3.8 KW | |||

| COMPRESSED AIR | 0.6 MPA600 L/MIN | |||

| MACHINE DIMENSION(MM) | 2000(3100)X1750X 1650 | 2000 (3200)X1750X 1700 | ||

| MACHINEWEIGHT | 1800 KGS | |||

Premade Pouch Packaging Dosing Systems

-

Premade Pouch Rotary Packaging Systems

Multi Filling granule, powder Liquid & Paste Pouch Packaging Machine

Rated 0 out of 5 -

Premade Pouch Rotary Packaging Systems

Premade Pouch Rotary Fill and Seal Powder Packaging Machine

Rated 0 out of 5 -

Premade Pouch Rotary Packaging Systems

Premade Pouch Rotary Fill and Seal Liquid & Paste Filling Machine

Rated 0 out of 5 -

Premade Pouch Rotary Packaging Systems

Premade Pouch Rotary Fill and Seal Granules Packaging Machine

Rated 0 out of 5 -

Premade Pouch Rotary Packaging Systems

Premade Pouch Rotary Fill and Seal Seal With Linear Scales for Granules

Rated 0 out of 5

How JR series works

Typical Pouch Sytles Can Bring In This Model

All You Need To Know About Premade Pouch Packaging Machines

As the owner of HonorPack, a company specializing in bag packaging machinery, I know firsthand how essential it is to stay up-to-date on the latest developments in the packaging industry. The premade pouch packaging machine has become increasingly popular, and for good reason. It offers an efficient and cost-effective solution for businesses looking to streamline their packaging processes. In this blog post, I’ll guide you through everything you need to know about these machines, including their types, components, and applications.

Premade Pouch Packaging Machines VS VFFS Packaging Machines

Pre-made bag packing machine is a kind of packing machine to fill products into pre-made bags and then seal them. Compared to the VFFS (Vertical Form Fill and Seal Packing Machine, which uses roll film to make bags), it can be used to pack many types and sizes of pre-made bags, and doesn’t have to change machine parts. By packing more attractive packages, this machine will help you win the market. When changing your packing style or packing specifications, also you will save the cost of changing the machine parts or machine models. (Usually VFFS machine can only pack one width type bags, if you change the bag size, you will need change the film size and bag formers.) However the premade bag price will be higher than roll film Bags.

| Pros & Cons | Premade Pouch Packaging Machines | VFFS Packaging Machines |

|---|---|---|

| Flexibility | Can handle various pouch styles (stand-up, flat, zippered, and spouted). | Limited to specific bag styles. Roll film Bags |

| Efficiency | Can handle multiple pouch sizes without changing parts or adjusting the machine. | Continuous operation allows for high speed. Changing the film size and bag formers |

| Quality | Better aesthetics and consistency due to precise manufacturing process and pre-made bag packaging. | Quality may vary due to potential alignment and sealing issues during high-speed operation. |

| Speed | Slower due to the need to open, fill, and seal premade bags. | Typically faster because of the single, continuous operation. |

| Cost | Higher initial investment due to the cost of premade pouches. | Lower material costs as bags are formed from a single roll of film. |

Which One is For You?

The choice between a premade pouch packaging machine and a VFFS machine depends largely on your specific needs and constraints.

If your primary concern is speed and lower material costs, a VFFS machine may be a better fit. These machines are also beneficial if your product requires simple pillow-style bags.

On the other hand, if you’re looking for flexibility in pouch styles and are willing to pay a bit more for higher quality presentation, a premade pouch packaging machine may be the way to go. These machines are also beneficial if your product requires more complex packaging such as stand-up or spouted pouches.

In the end, it’s crucial to consider the specific needs of your product and your operational constraints before deciding on the right packaging machine for your business.

Types of Premade Pouches

Premade pouches are available in various forms, including:

- Stand-up pouches

- Flat pouches

- Gusseted pouches

- Spouted pouches

- Zipper pouches

- 4-side seal poucher

Each type serves specific packaging needs and can be used with the appropriate premade pouch packaging machine.

— Bag Size Layout Reference

Sales always will ask you for the bag type and bag size, also the product type/size and packing weight range.

Here are the table show you the bag type that different machine can pack.

What is a Premade Pouch Packaging Machine?

A premade pouch packaging machine is a device designed to fill and seal premade pouches or bags. As its name suggests, these machines take bags that have been previously manufactured, fill them with product, and then seal them. These machines can accommodate a variety of pouch types, including stand-up, flat, and zippered bags.

Types of Premade Pouch Packaging Machines

There are two primary types of premade pouch packaging machines:

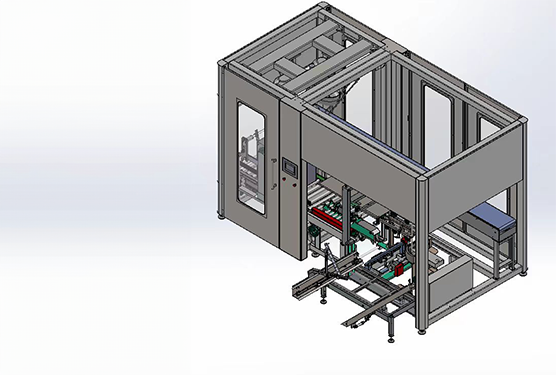

Rotary Premade Pouch Packaging Machines: These machines use a rotating turret to pick up, fill, and seal pouches. They offer high speeds, handling multiple pouches simultaneously, making them ideal for high-volume production.

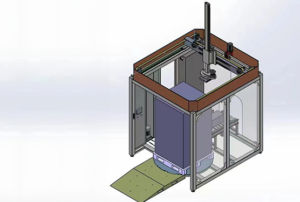

— Vacuum Rotary Premade Pouch Packing Machines: These types of machines are a variant of the rotary premade pouch packaging machines that include an additional vacuum sealing step in their process. Vacuum Rotary Packing Machines pick up, fill, seal, and vacuum seal pouches using a rotating turret.Linear Premade Pouch Packaging Machines: Linear machines move pouches along a straight conveyor, filling and sealing them one at a time. These machines are typically more compact, making them suitable for smaller production spaces.

Premade Pouch Packaging Machine Packaging Process

Premade Pouch Rotary Packing Machine is an automatic packing machine which automatic feeding & pick up pouches, coding, open the pouches, filling products into the pouches, then sealing & output.

Pouch Selection: This process begins with the machine picking up an individual bag from a pre-supplied stack of premade pouches, typically through a robotic arm or a similar automated mechanism.

Pouch Opening and Optional Gas Flushing: Once a pouch has been picked up, it is opened in readiness for filling. Machines equipped with a gas flush option add an additional step to this process. They fill the bag with an inert gas, such as nitrogen, to displace oxygen, preserving the product’s quality and extending its shelf life.

Product Filling: The now open pouch is filled with the product, facilitated by the machine’s advanced dispensing mechanisms. These mechanisms are designed to handle a vast range of products: from liquids, powders, granules, to solid food items and non-food items.

Pouch Sealing and Discharge: After filling, the machine moves to seal the pouch using either heat sealing or ultrasonic sealing techniques. Once sealed, the filled and sealed pouch is then discharged from the machine, ready for further processing or distribution.

Option: Nitrogen Flush, Vacuum, Multi-Filling, Spout Pouch (Conner or Center), Zip Pouch

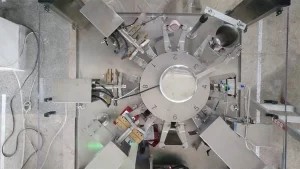

Premade Pouch Packaging Machines Stations Work Flow

The Rotary Packer consists of 8 work station and performs intermittent rotational motion.

*May different depending on product nature and customers’ requirement.

- Feeding Pouch & Pick Up By Gripper

- Coding & *Open Zipper

- Pouch Top & Bottom Open

- 1st Fill

- 2nd Fill

- *3rd Fill or * Pre-Heat Seal

- Heat Seal

- Embose Seal & Out Feeding

1)Bag loading and bag transferring

bag loading:Approximately 200 to 300 pieces of empty bags are supplied to the machine automatically when the

operator puts the bag on the bag stacker (Bag Magazine)

bag transferring:A pair of pneumatically operated clamps lift the empty bag from the feeder and move it to the

clamping device on the rotary table.

2)Optional (date coding)

Standard with hot stamping coder, the information such as production date expiration date (optional) with print to

pouch here. Option: Ink Jet Coder, Thermal Transfer Coder

3)Open bag & detecting open status

With vacuum pad, air nozzle, open blade & sensor; this station works open pouch from both top & bottom. Under the sensor working, incorrect open or no pouch load, will no filling in next filling stations.

4)Filling products:

With correct open detected, products will filled from dosing system, like cup feeder, combination scales, auger

filler….

5)Spare station:

Filling 2nd times

6)Pre-sealing station:

Constant heat seal bar (0℃ ~ 200℃) sealing the pouch mouth. No pouch, no filling, here will no sealing.

7)Sealing station:

Sealing the pouch with a precious temperature ensure tight sealed. No pouch, no filling, here will no sealing.

8)Cool sealing, embossing coding and discharge station:

Cold sealing bar will press the sealing pattern on the sealing range. Option to embossing product information by the stamping mold load in sealing bar. Gripper will release, pouch will discharge to the out feed conveyor.

Applications of Premade Pouch Packaging Machines

Food Industry

Snacks: Premade pouches are perfect for packaging snacks like chips, popcorn, and nuts, as they provide an excellent barrier against moisture and oxygen, keeping the products fresh.

Frozen Foods: For frozen fruits, vegetables, or ready meals, premade pouch packaging machines offer excellent seal integrity to prevent freezer burn and prolong shelf life.

Liquids and Sauces: For products like soups, sauces, and ready-to-drink beverages, spouted pouches can be filled and sealed using these machines.

Pharmaceutical Industry

Premade pouch packaging machines can fill and seal pouches for pharmaceutical products like pills, powders, and liquids. They offer superior seal integrity which is crucial in maintaining product efficacy and preventing contamination.

Pet Food Industry

For dry kibbles, treats, and wet pet food, premade pouches offer resealable options like zipper closures, ensuring the product remains fresh after opening.

Agriculture Industry

Seeds, fertilizers, and other agricultural products can be efficiently packed using premade pouch packaging machines. The machines can handle heavy-duty bags required for these types of products.

Cosmetics Industry

Powders, creams, lotions, and other cosmetics can be packaged into small, convenient pouches. These pouches can be made to stand up for better display on store shelves.

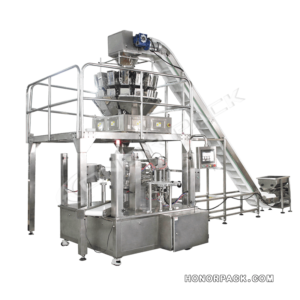

Premade Pouch Packaging Machine With Different Dosing/Filling Systems

Depending on the characteristics of the product, different metering systems can handle a wide range of products.

Equipped with Z-shape bucket elevator and combination scale, it is widely applied to candies, microwave popcorn, cookies, nuts, rice, coffee beans, crops, peanuts, etc.

Equipped with piston filler as the dosing system, it is widely applicated to packing liquid and paste, such as detergent, softener, shampoo, shower gel, milk, water, juice, soybean sauce, oil, ketchup, mayonnaise and so on.

Equipped with Augur Filler and Screw Elevator, it is widely applied to packing powder, such as detergent powder, milk powder, flour, spice, coco powder, ground coffee, and so on.

Equipped with multi-head filling systems, allowing for the simultaneous filling of multiple products into a single pouch.

-

Premade Pouch Rotary Packaging Systems

Multi Filling granule, powder Liquid & Paste Pouch Packaging Machine

Rated 0 out of 5 -

Premade Pouch Rotary Packaging Systems

Premade Pouch Rotary Fill and Seal Powder Packaging Machine

Rated 0 out of 5 -

Premade Pouch Rotary Packaging Systems

Premade Pouch Rotary Fill and Seal Liquid & Paste Filling Machine

Rated 0 out of 5 -

Premade Pouch Rotary Packaging Systems

Premade Pouch Rotary Fill and Seal Granules Packaging Machine

Rated 0 out of 5 -

Premade Pouch Rotary Packaging Systems

Premade Pouch Rotary Fill and Seal Seal With Linear Scales for Granules

Rated 0 out of 5

Premade Pouch Packaging Machine Integration with Other Equipment

Premade pouch packaging machines can be integrated with various other pieces of equipment, such as:

- Metal detectors

- Checkweighers

- Conveyors

- Product feeders

- Labelers and printers

This integration creates a seamless packaging line, improving efficiency and reducing downtime.

Automation and Control Options of Premade Pouch Packaging Machines

Premade pouch packaging machines offer various automation and control options, such as:

- Touchscreen interfaces for easy operation and control

- Programmable logic controllers (PLCs) for precise control over machine functions

- Recipe storage and recall for quick changeovers between products

- Remote monitoring and diagnostics for proactive maintenance

Factors to Consider Before Purchasing a Premade Pouch Packaging Machine

When selecting a premade pouch packaging machine, consider the following factors:

- Production capacity and speed requirements

- Available space for the machine

- Types and sizes of pouches to be filled

- Types of products to be packaged

- Integration with existing equipment

- Budget and return on investment

In order to provide you the correct packing equipment for your business. We hope we can get more information from your side. The under questions list will help us reduce the checking time and save time for you. You can download the Excel table at the end of this part.

download the Excel table at the end of this part.

Question List | Your Answer | Note |

01 What kind of product you are going to pack? If we can get some samples/photos to assess? | ||

02 Could you tell us the packing weight range? | ||

03 Do you have the sample bags and bag size? | ||

04 If you can send us your bag photos or design? If you can send us your bags to our factory address to test? | If send sample bags need around 100-200 bags. | |

05 Could you let us know your plant size or layout? Is there any celling height limit? | ||

06 What’s your factory power supply voltage type? | ||

07 When you are going to apply this set of machines? | ||

08 For self-use or resale to others? Which Country? | ||

09 The packing speed requirements. | ||

10 Other requirements for the packing process. |

Evaluating Premade Pouch Packaging Machine Manufacturers

To choose the best premade pouch packaging machine for your business, follow these tips:

- Assess your production needs and requirements

- Research reputable manufacturers and compare their offerings

- Request machine demonstrations and samples

- Check for after-sales support and service options

- Consider the total cost of ownership, including maintenance and spare parts

Maintenance of Premade Pouch Packaging Machines

Regular maintenance is essential for the longevity and performance of your premade pouch packaging machine. Some maintenance tasks include:

- Cleaning the machine and its components

- Lubricating moving parts

- Checking and adjusting sealing parameters

- Replacing worn or damaged parts

Always refer to the machine’s manual for specific maintenance guidelines and schedules.

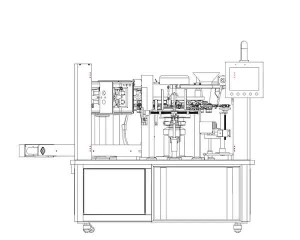

Premade Pouch Packaging Machine Dimensions and Footprint

The size of a premade pouch packaging machine depends on the specific model and type. Rotary machines tend to be larger, while linear machines are generally more compact. Consider your available production space when selecting a machine to ensure it fits comfortably within your facility.

L1970mm

W1650mm

H1700mm

Material: Sus 304

Weight:1650 kg

Designer: Mr. Jeon

Warranty:2 years

Conclusion

Premade pouch packaging machines have become an increasingly popular choice for businesses looking to streamline their packaging processes and improve product presentation. With a wide range of machine types, capabilities, and applications, there is a premade pouch packaging machine suitable for almost any industry. When selecting the right machine for your needs, consider factors such as production capacity, available space, pouch types, and product compatibility. By investing in the right premade pouch packaging machine, you can increase efficiency, reduce waste, and enhance your product’s appeal to customers, all while ensuring a favorable return on investment.